Prime Steel Processors Private Limited

Infrastructure

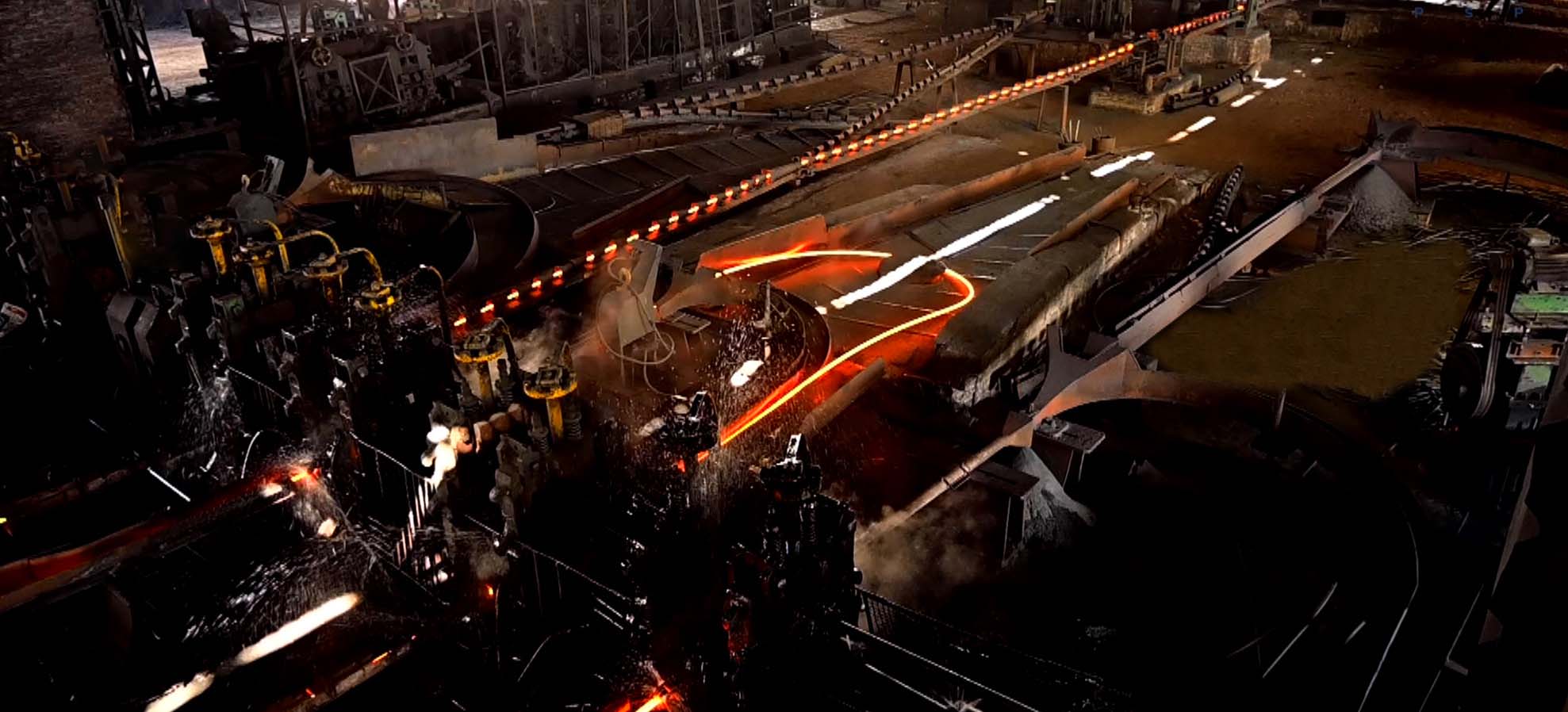

Being a forward and backward integrated business, we are in possession of state-of-the-art technologies that ensures the highest standards in every aspect of our operations. Our Steel Melting Shop and Rolling Mill are equipped with several cutting-edge equipment, enabling seamless production processes and ensuring high quality outputs.

STEEL MELTING SHOP

| Equipment | Model/Make | Capacity |

|---|---|---|

| 2 Induction Furnaces | Electrotherm | 30 TONNE (each) |

| Induction Furnace 4.5 TONNE for Alloy Steel Ingot making | Electrotherm | 4.5 TONNE |

| 1 LRF (Ladle Refining Furnace) | Electrotherm | 35 TONNE |

| CCM (Continuous Cast Machine) with the facility of PLC control for cooling parameters & casting speed & Caster 6*9*15 double strand | Electrotherm | |

| 1 Vaccum Degassing | Edward Pumps & VAI-INDIA | 35 TONNE |

| EMS (Electro Magnetic Stirrer) | Ergolines Italy | |

| Wire Feeding Machine- Double Strand Wire Feeder, Model- CWF(D) | Minex Metallurgical Co.Ltd. |

ROLLING MILL

| Equipment | ||

|---|---|---|

| Horizontal/Vertical Continuous Mills | Fully automatic state of the art Horizontal/Vertical continuous rolling mill consisting of 16 stands, 4 cantilever stand | |

| 2 Garret Coiler | Garret Line for coiling for wire rod size from 12mm to 40mm (each). | |

| Block Mill | 8 Stand Latest Block Mill | |

| Cooling Bed | Cooling bed Braking Slide | |

| Induction Billet Heater | Induction Billet Heater by Electrotherm | |

| Descaling System | Primary and Secondary scale breaker, High pressure water jet pump type make pressure jet |